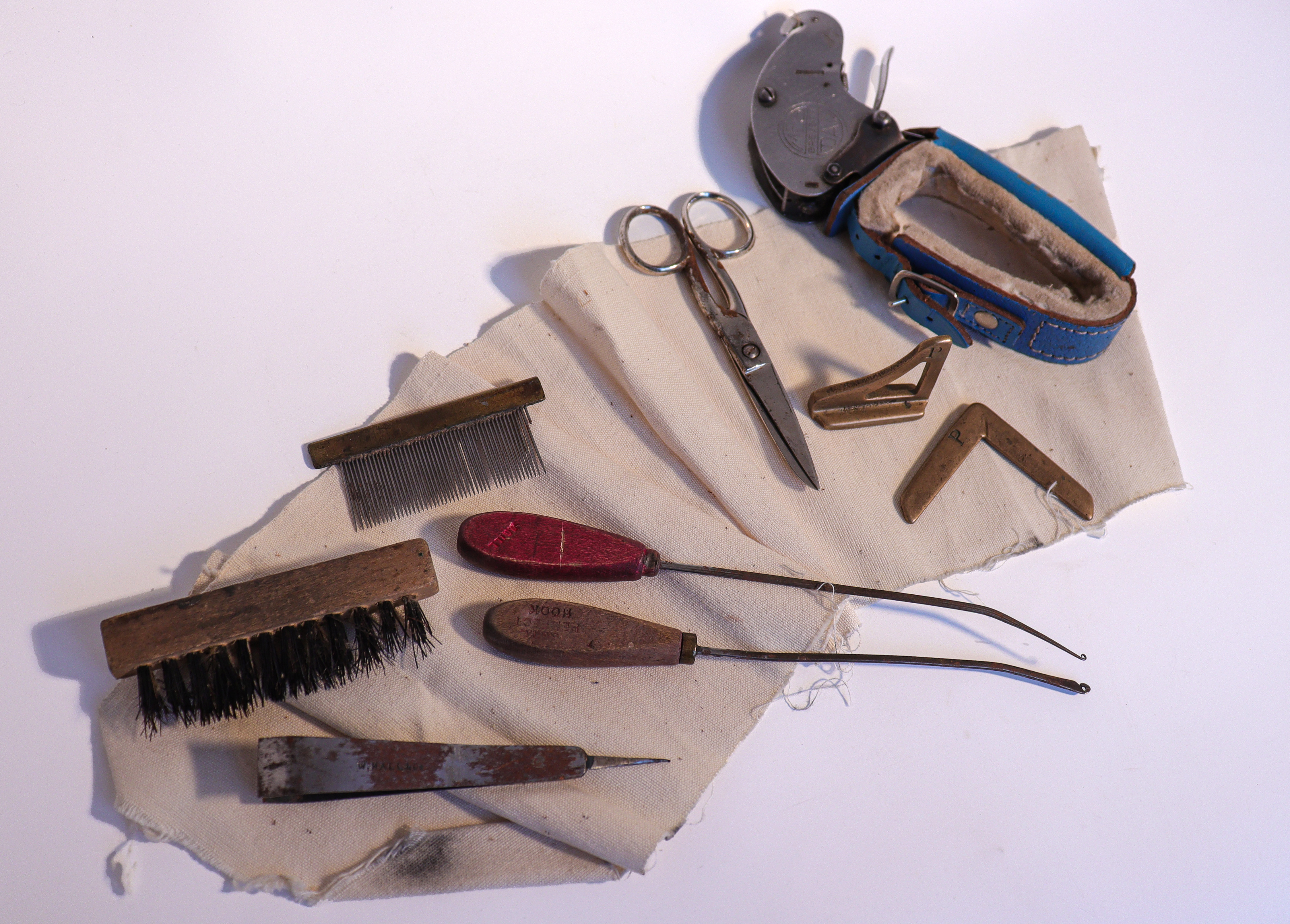

Weaver's Tools

Description

Weavers would traditionally be paid ‘piece rate’, originally a fixed rate for a standard measured ‘piece’ of woven cloth. In the mechanised factory this was still the basis of their pay, so any faults, delays or breakdowns would cost them in wages. They carried a small kit of tools to effect quick fixes to the cotton warp or weft such as broken threads. Anything going wrong with the loom itself would require the tackler to be called.

At the height of cotton production in the county, in the full year 1912/1913, woven cotton cloth production stood at around 8 billion yards – which is 4.5 million miles of cloth. One year's production would take you to the moon and back nine times.

Following the introduction of the power loom in the early part of the 19th century, weavers had quickly become by far and away the largest part of the textile industry workforce in Lancashire. At Queen Street Mill in Burnley, a typical weaving mill now run as a museum by Lancashire County Council, the weaving shed held over 900 looms. With one weaver to four looms this required over 200 weavers to operate at anything like full capacity. It was one of four or five similarly sized mills in the small village of Harle Syke just outside Burnley, not to mention the twenty or more in the town itself. It's not surprising that by 1900 60% of Lancashire’s population, over 600,000 people, were employed in the textile industry.

Details

- Accession number

- DISP.198

- Category

- Industrial History

- Materials

- wood

metal

cotton

leather

On display

50 Objects Exhibition at Helmshore Mills Textile Museum 6 June - 31 October 2025. Search www.lancashire.gov.uk for Helmshore Mill opening times.